Today we would like to take the time to talk about aluminum packaging in the single-use beverage market.

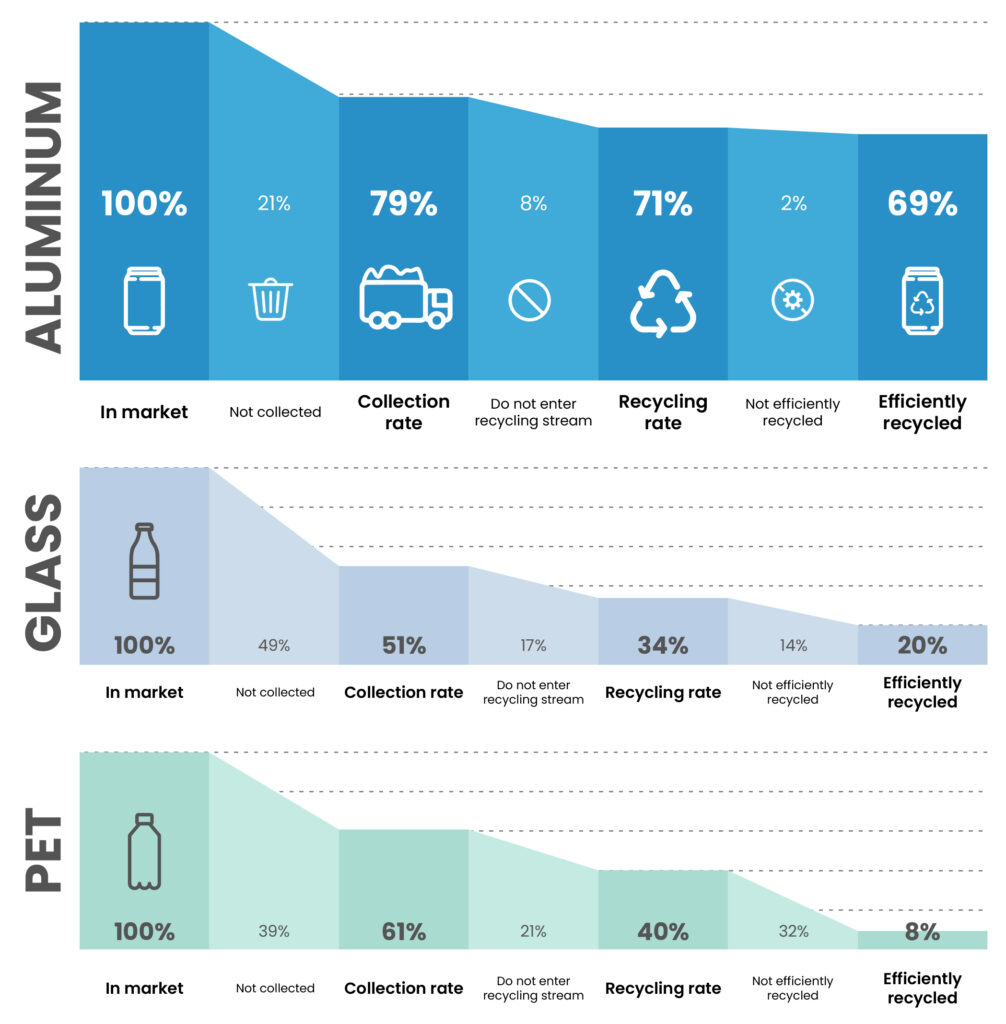

Although we are all familiar with beverage cans, not everyone is aware of the efficiency of their recycling process. Aluminum packaging for single-use beverages has the highest recycling efficiency rate in the market, reaching as high as 90% once the material is collected, which, combined with its 79% collection rate, results in 71% of material actually being recycled.

Now, let’s compare it with the other 2 most used materials for single-use beverage packaging: glass and plastic (PET). Glass has a 34% recycling rate, while PET has a 40% recycling rate, which, compared to 71% for aluminum, is quite a noticeable difference.

These results are mainly due to the lower collection rates of glass and PET, in addition to the lower recycling efficiency of each, which is caused by the fact that these materials must comply with certain characteristics (such as color and number of times of reuse) in order to be recycled.

Finally, if we also consider the capacity of aluminum to be recycled infinite times, we can conclude that aluminum cans are not only the most recycled beverage container, but also the one with the highest recycling potential in the market, being possible to recycle it endless times to turn it into the same or another product.

We invite you to find out more about aluminum, learn about its capabilities, its participation rate in the recycling stream and join the road to sustainability with us!

* Values and information from International Aluminum Institute report "A Circularity Case For Aluminum Compared With Glass And Plastic".